Filters

Découvrez aussi

Here, you’ve entered a space of sharing—sharing our passion for raw Japanese denim, patina-rich cottons, the deep indigo hues of Italian fabrics, the beauty of eco-friendly washes, the charm of selvedge edges, and the vintage spirit of bleached denim. Our love for authentic denim goes way back: our very first piece in 2012 was a pair of jeans... and some of you are still wearing them today!

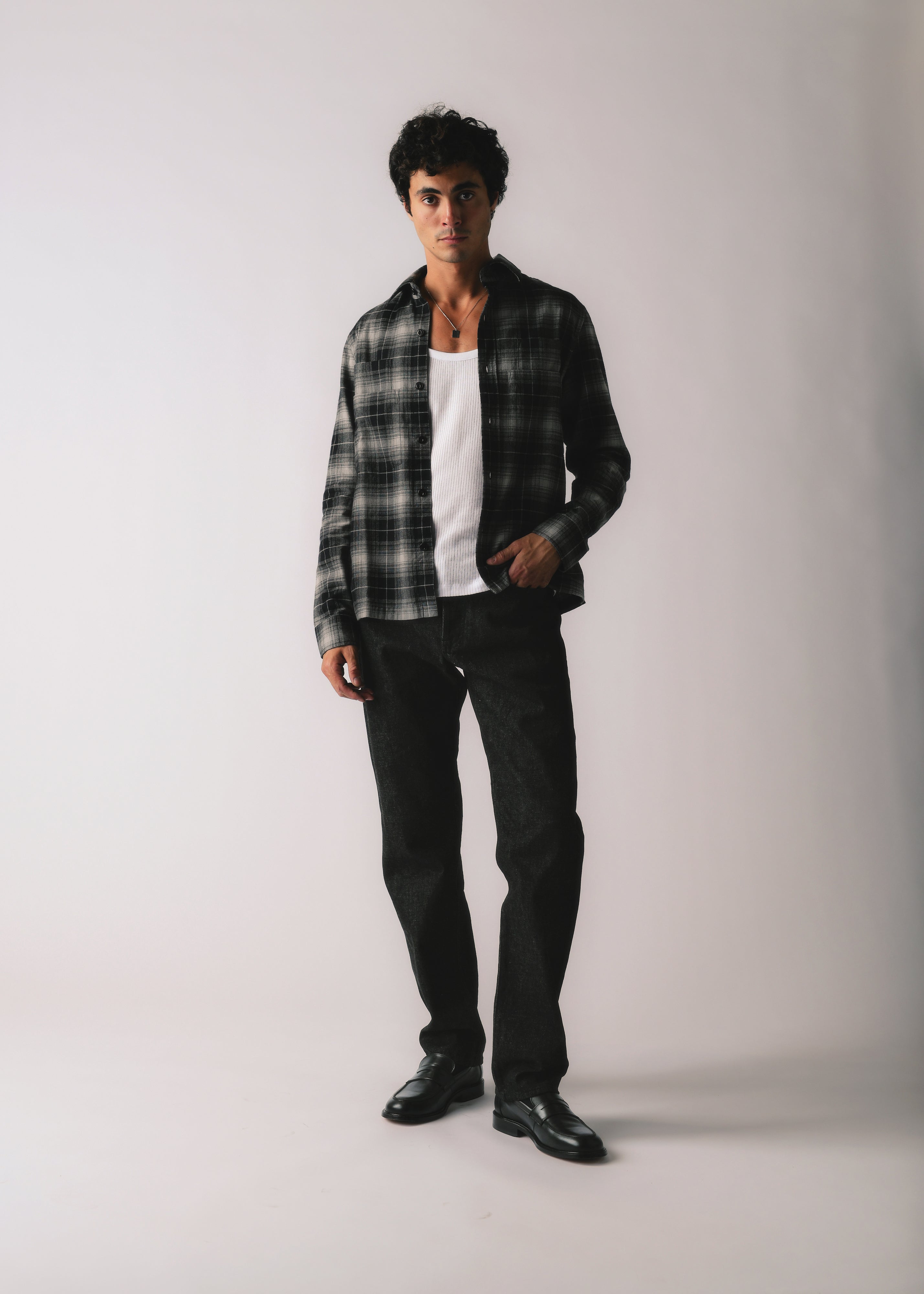

Whether you're after raw Japanese denim, selvedge jeans, or stretch denim, our collection offers a range of styles and fits to suit every preference and body type. From high-waisted to straight-cut, slim to semi-slim, we explore different cuts to create timeless styles.

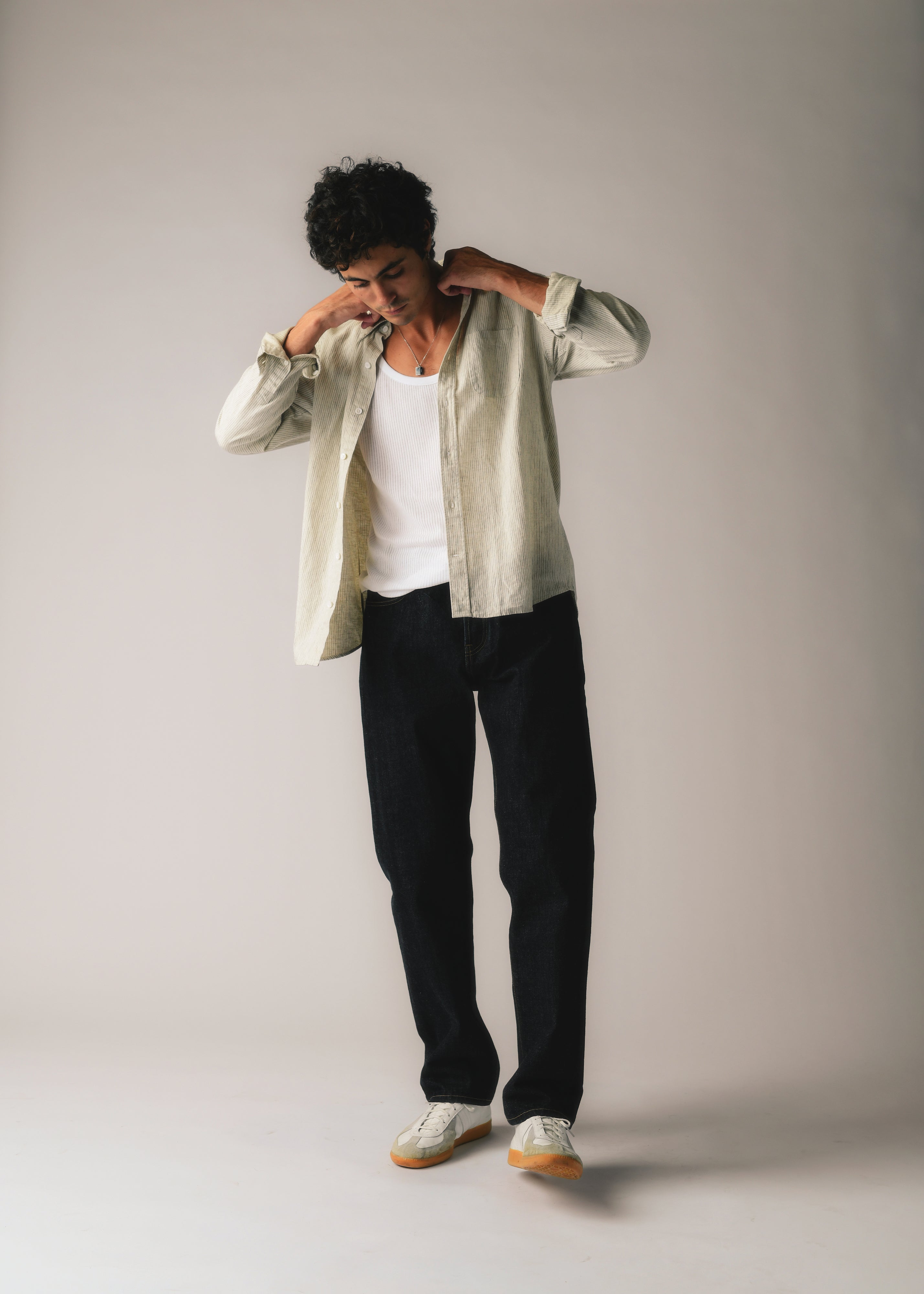

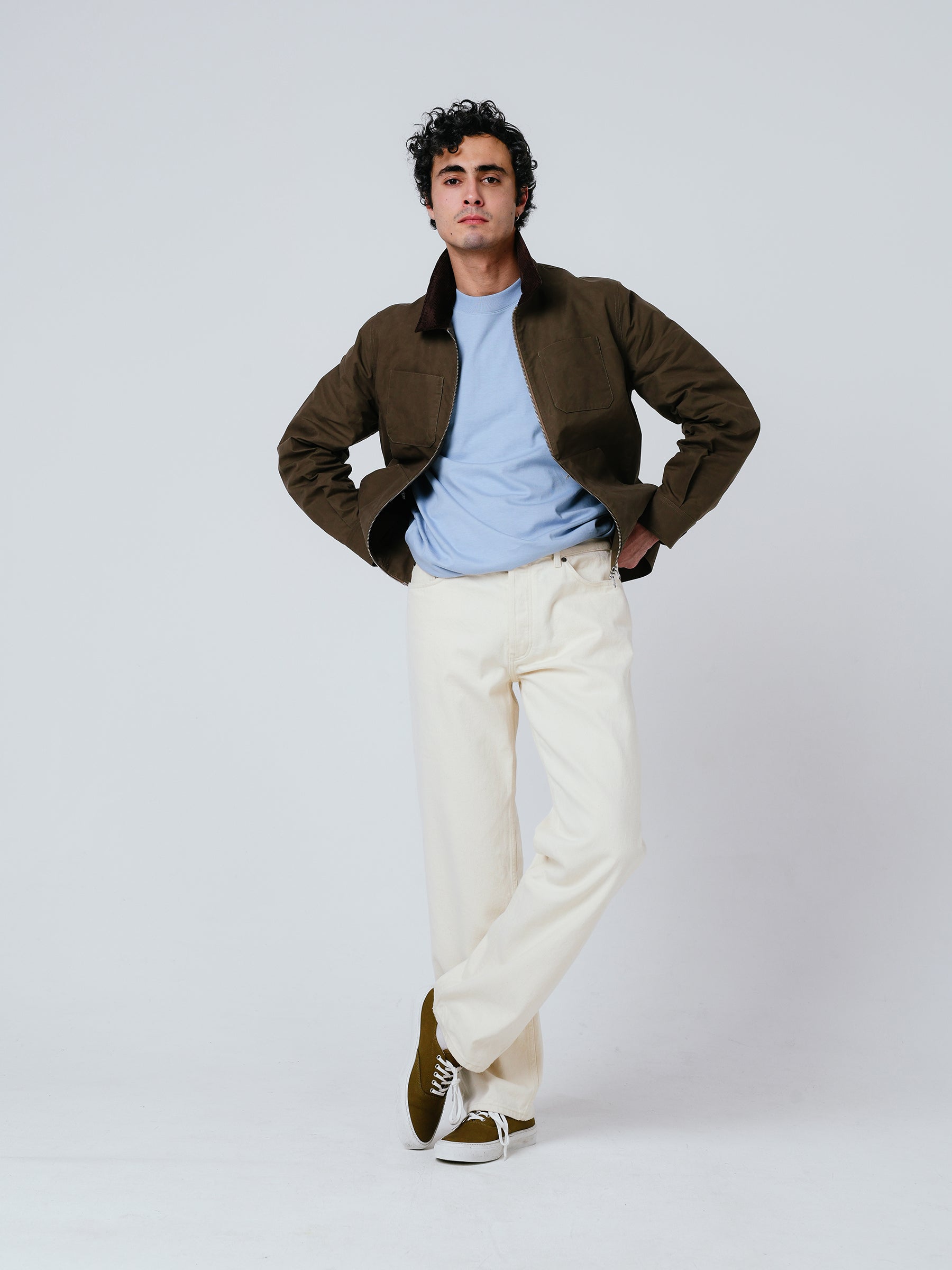

Our jeans are crafted for versatility, just like the rest of our collection. Whether for a casual day or a more formal occasion, our jeans provide a timeless and sophisticated look. Pair them with our shirts, t-shirts, and jackets to create outfits that express your personal style.